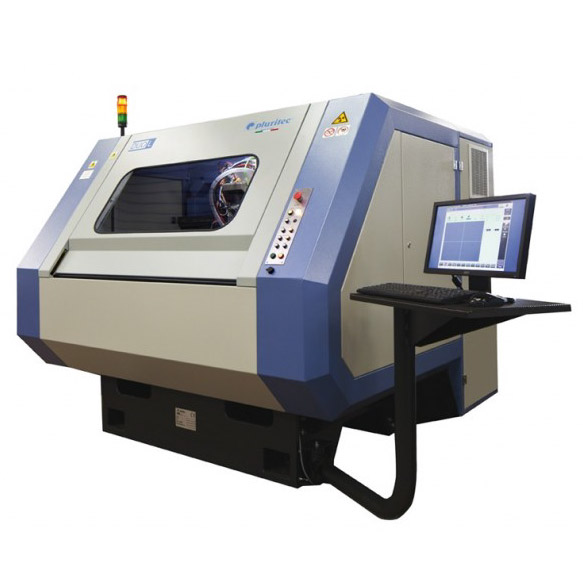

C-FLEX

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

- Two independent heads on linear motors and linear guides

- Each head can be configured with a dedicated spindle for drilling and routing

- Large Format 780x740mm (30.50×29.00″) / 780x1070mm (30.50×42.00)

- All axis driven by linear motor for speed and accuracy

- Table runs on a gantry system for maximum performance and positioning control

- High speed drilling spindles from 200k up to 250k rpm for micro drilling

- High torque routing spindles from 5k to 125K rpm for heavy duty routing to precision routing

- Depth control drilling and routing using contact surface sensing, linear scale and mapping

- HD CCD Camera with RGB lighting registration solutions for flip drilling, back drilling and sequential build up applications.

- High capacity tool holder up to with 1386 positions per spindle operated independently from machine

- Code reader for panel/job recognition

- Automatic loading unloading system to run the machine unmanned.

- Powerful IPC CNC Windows OS with full and easy to use user interface

- Automatic bush change for micro-drilling

- Panel clamping system

- Joystick with software tools for manual camera operation

- Code reader / Panel marking

- Metal routing kit with tool cooling

- Floating pressure feet for pinless routing

- Automatic insert change for micro routing application

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.