INNOVATION IN PRINTED CIRCUITS BOARDS SOLDER MASK APPLICATION

COAT AND TACK CURE READY FOR IMAGING IN 20 MINUTES!

DOUBLE/SINGLE SIDE SPRAY COATING SYSTEM

SIMPLE MAINTENANCE AND EASY CLEANING

LOW OVERSPRAY

EXCELLENT GAP FILLING AND ENCAPSULATION

EXCELLENT TRANSFER EFFICIENCY

ECOSPRAY A1S

AUTOMATIC SINGLE SIDE SPRAY COATING

Single side Spray coating system | Automatic panel loading and unloading with dedicated buffers | Simple maintenance and easy cleaning | Up to 3 heated guns | Low overspray | Excellent gap filling and encapsulation | Special multi-pass SFS function allows sequential spray layers with different parameters | Excellent transfer efficiency (±80%) | Productivity up to 100 single sided coated panels (460x610mm – 18×24”) per hour with continuous spray from panel to panel (panels in a row) | Spray flow stabilisation with security pressurised air tank | Available in line with all ECODRYER H.E. ovens

ECOSPRAY A2S

AUTOMATIC DOUBLE SIDE SPRAY COATING

Double side Spray coating system with SFS system (Spray-Flip-Spray ) | Automatic panel loading and unloading in-line with EcoDryer | Simple maintenance and easy cleaning | Large PLC screen and recipes with joblist | Up to 3 heated guns – Low overspray | Automatic color change and cleaning (optional) | Excellent gap filling and encapsulation & transfer efficiency (±80%) | Productivity 20-30 double sided coated panels per hour with100g/m2 ink deposit | Special multi-pass function allows sequential spray layers with different parameters | Spray flow stabilisation with security pressurised air tank | Security entry sensor for panel length check | Panel thickness range with pneumatic clamping system 0,8-3,5 mm (0.03×0.14”) | Panel size standard clamps: Min 300×200 mm (12×8”) – Max 710×650 mm ( 28×25.5”) | Panel size pneumatic clamps: Min 350×200 mm (14”x8”) – Max 710×650 mm ( 28×25.5”) | Different format available on request

ECOSPRAY DS

DOUBLE SIDE SPRAY COATING

Double side Spray coating system with SFS system (Spray-Flip-Spray ) | Automatic panel loading and unloading in-line with EcoDryer | Simple maintenance and easy cleaning | Large PLC screen and recipes with joblist | Up to 3 heated guns – Low overspray | Automatic color change and cleaning (optional) | Excellent gap filling and encapsulation & transfer efficiency (±80%) | Productivity 20-30 double sided coated panels per hour with100g/m2 ink deposit | Special multi-pass function allows sequential spray layers with different parameters | Spray flow stabilisation with security pressurised air tank | Security entry sensor for panel length check | Panel thickness range with pneumatic clamping system 0,8-3,5 mm (0.03×0.14”) | Panel size standard clamps: Min 300×200 mm (12×8”) – Max 710×650 mm ( 28×25.5”) | Panel size pneumatic clamps: Min 350×200 mm (14”x8”) – Max 710×650 mm ( 28×25.5”) | Different format available on request

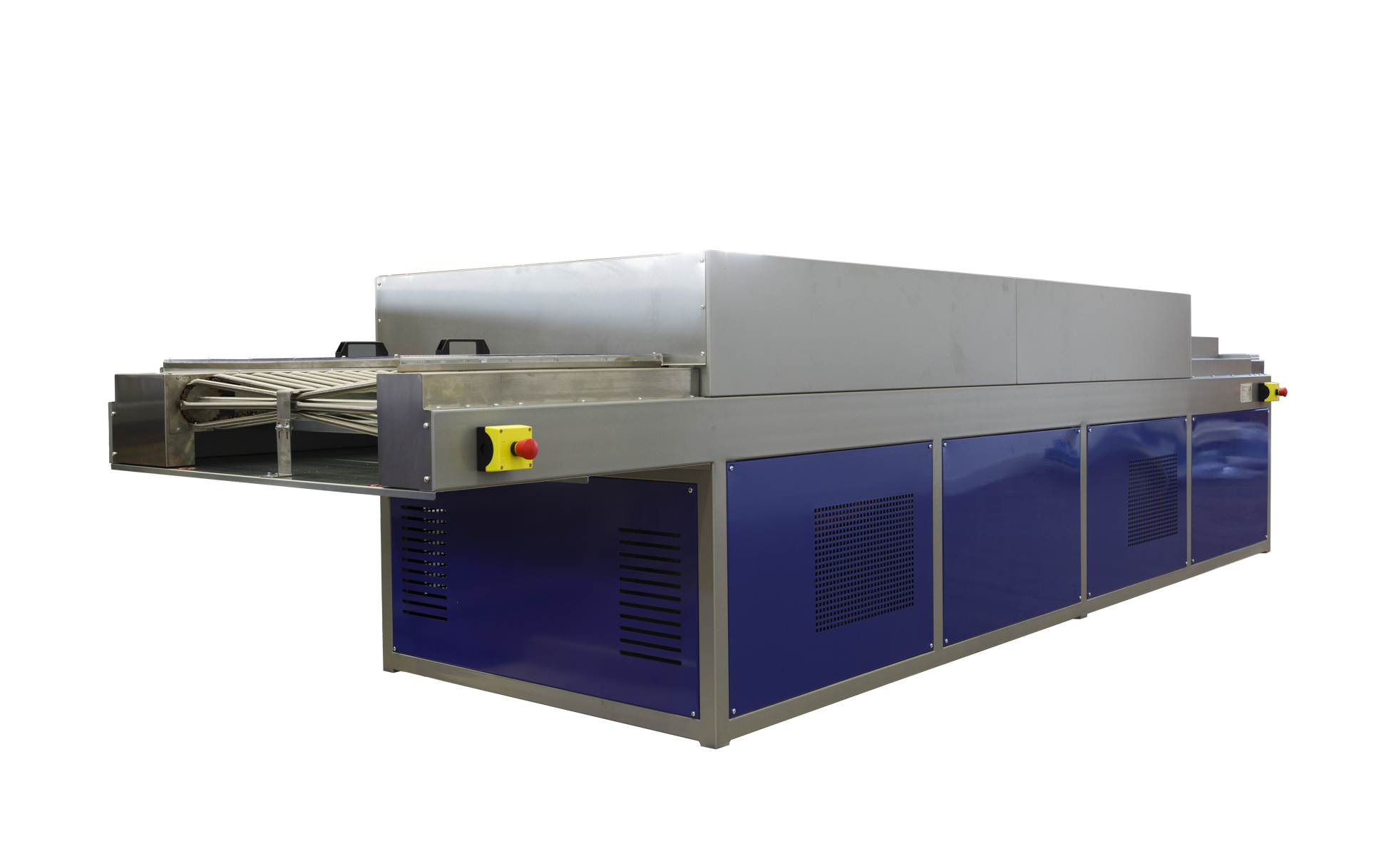

THERMAL OVENS

product features

EcoDryer is a conveyorized oven suitable for “tack” drying of both conventional and photoimageable solder masks | Available as a stand stand alone system or in combination with Ecospray | Available with automatic loading unloading buffers | Featuring dynamic hot air drying with dedicated air circulation system that grants consistency in treatment using the same temperature profile and distribution across the panel | Great care has been dedicated to the generation of a consistent air flow generated by a system of heating resistances, thus granting uniformity of temperature on the panel surface | A dedicated fan placed on the conveyor exit section blows ambient temperature air, thus cooling down the panel

LOADERS UNLOADERS

product features

Automatic loading unloading buffers with wheels | Roller-bench tables | Flippers and deviator| Different configurations and capacity