50 Years of Manufacturing History IN PCB FABRICATION

Field Proven Design and Patented ”IP”

Superior Construction Quality with Solid Thick PPT

STAINLESS STEEL AND TITANIUM

- PANEL WIDTHS 650 (25,5”) OR 760 MM (30”) – LARGER ON REQUEST

- STANDARD PANEL THICKNESS FROM 0,5 TO 7 MM (0.020” TO 0.270”)

- ULTRA-THIN SYSTEM FOR 0,025 / 0.001” THICKNESS

- UP TO 12,7 MM. (.500”) WITH THE THICK BOARD OPTION

- DIGITAL PROCESS CONTROL

- “SMART” ETCHING TECHNOLOGY WITH INDIVIDUALLY DIGITALLY CONTROLLED BARS

- AUTO-CLEANING SYSTEMS

- AUTOMATION FOR LOADING AND UNLOADING

SCRUBBEX – BRUSHING MACHINE FOR PCB

product features

These STAINLESS STEEL solid and compact units can be employed for any surface treatment involving the use of abrasive brushes such as scrubbing, deoxidising, deburring, preparation of solder to fusing, hot-air levelling and solder mask application.

Precise adjustment, fast replacement and oscillation of the brushes allow to use any type of abrasive wheel (compact or of abrasive-impregnated bristles) thus ensuring the highest versatility.

Standard configurations:

Model 2B with one upper and one lower brush.

Model 4B with two upper and two lower brushes.

PUMIFLEX – BRUSHING MACHINE FOR THIN MATERIAL

now available with roll to roll automation

product features

STAINLESS STEEL solid and compact unit. Thin inner layers of multilayers, flexible circuits, as well as rigid boards are perfectly cleaned on both sides by means of rotating nylon brushes and a suspension of abrasive and water. The PUMIFLEX-SHD/A is unique in its field thanks to its computerized “CLEVERBRUSH” system by which computer-controlled self-bracking motors will stop the brushes and/or start them in the proper direction and at the right time so that any damage to thin foils is avoided.

PLATEMASTER – MULTILAYER PRESS PLATES CLEANING AND COATING SYSTEM

product features

Stainless steel unit to easily remove all lamination residues from separator plates. “Anti-sticking” coating uniform application on plate surface. Eliminates requirements for release film .

-Avoid defective multilayers due to residues on plates during lamination.

-Protective film prevents residues to stick on the surface making their removal easier.

-Longer plate life and less brush consumption thanks to the ultra-thin and perfectly flat coating which permits cleaning with a light brushing action.

-Modular design allows to insert the unit in any existing or new line.

DES – DEVELOP ETCH STRIP LINES

product features

Develop Etch and Strip Modular line made of Polypropylene and Stainless Steel or titanium for alkaline or acid etching solution in the manufacture of printed circuit boards. These machines are ideally suited for inner layer as well as for outer layer etching process.

Each line can be fully customised from entry conveyor to etching chamber, anti pollution, rinsing, drying chambers.

“Smart” digital etching control for top and bottom and edge to edge. Perfect uniformity avoid overreach or under etch on 100% of the surface.

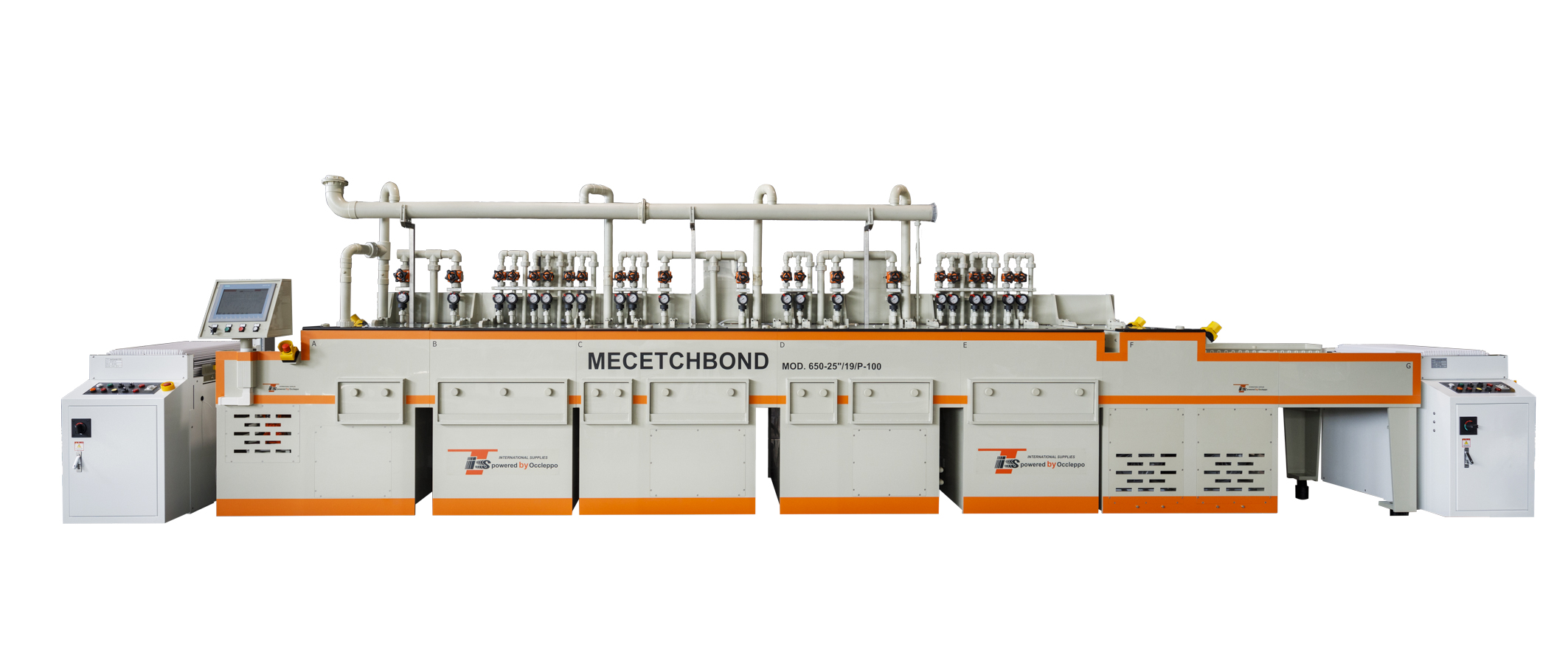

SURFACE PREPARATION – MECETCHBOND

product features

Modular line made of Polypropylene and Stainless Steel units for printed circuits board internal layers surface preparation with micro copper treatment

Each line can be fully customised from entry conveyor to cleaning, rinsing, micro etching , drying chambers.

The modular design offers the possibility of adding modules for developing, rinsing or s to meet all production requirements.

The configuration line is related to the specification of the of chemical supplier; lines has been produced and installed in cooperation with different chemical suppliers.

SURFACE PREPARATION – MICROETCHING

product features

Modular line made of Polypropylene and Stainless Steel units for printed circuits board internal layers surface preparation with micro copper treatment

Each line can be fully customised from entry conveyor to cleaning, rinsing, micro etching , drying chambers.

The modular design offers the possibility of adding modules for developing, rinsing or s to meet all production requirements.

The configuration line is related to the specification of the of chemical supplier; lines has been produced and installed in cooperation with different chemical suppliers.

Developing

product features

Modular line made of Polypropylene and Stainless Steel units to develop alkaline dry-films and liquid photosensitive imaging film used in the manufacture of printed circuit boards.

Each line can be fully customised from entry conveyor to developing amd rinsing chambers.

The modular design offers the possibility of adding modules for developing, rinsing or s to meet all production requirements.

ALKALINE AND ACID ETCHING

product features

Alkaline or Acid etching line made of polypropylene and titanium for alkaline or acid etching solution in the manufacture of printed circuit boards.

These machines are ideally suited for inner layer as well as for outer layer etching process.

Each line can be fully customised from entry conveyor, soft etching, etching chamber, rinsing, drying and exit modules.

“Smart” digital etching control for top and bottom and edge to edge. Perfect uniformity avoid overreach or under etch on 100% of the surface.

STRIPPING

product features

Tin Stripping Lines Line made of highest quality Polypropylene and Stainless Steel AISI 316 or titanium in the fabrication of printed circuit boards.

This series is a combination of horizontal Chemical Spray, Chemical Immersion and Rinse modules with or without Force Fluid Flow Manifold and it is perfectly suited for the production of stand alone Tin Stripping lines or in combination of Dry film Stripper and Alkaline Etcher for Outerlayer production lines.

SES – STRIP ETCH STRIP LINES

product features

Strip Etch and Strip Modular line made of Polypropylene and Stainless Steel or titanium for alkaline or acid etching solution in the manufacture of printed circuit boards. These machines are ideally suited for inner layer as well as for outer layer etching process.

Each line can be fully customised from entry conveyor to etching chamber, anti pollution, rinsing, drying chambers.

“Smart” digital etching control for top and bottom and edge to edge. Perfect uniformity avoid overreach or under etch on 100% of the surface.

OSP

product features

OSP line for Atotech and Entek solutions.

Degreasing, rinsing, micro-etching, rinsing, post-dip, rinsing, dryer, OS-TechSit, dryer, cascade rinsing, dryer. Made of Polypropylene and Stainless Steel or titanium. Each line can be fully customized.

“Smart” digital control for top and bottom and edge to edge spray pressure to grant total parameters control and process control / repeatability.

PRE HAL

product features

PRE HAL line

Boards preparation for HAL process.

POST HAL

product features

POST HAL line

Boards treatment POST HAL process.