X-RAY MULTILAYER AND INNER-LAYER BOARDS COORDINATE MEASURING

ADVANCED MEASURING AND PATTERN RECOGNITION TOOLS

COMPREHENSIVE DATA ANALYSIS PACKAGE AND REPORTING

FINAL QUALITY CHECK CERTIFICATE

X-RAY MEASURING TECHNOLOGY

- MULTIPLE SHAPES DETECTION AND PATTERN RECOGNITION

- QR QC CODE READERS ON INNER LAYER AND OUTER LAYER

- ON LINE PANEL MARKING / SERIALIZATION FOR TRACEABILITY

- AUTOMATIC ERROR SCALING CLASS SORTING

- FACTORY 4.0 / M.E.S. INTEGRATION

- COMPLETE STATISTICAL PACKAGE

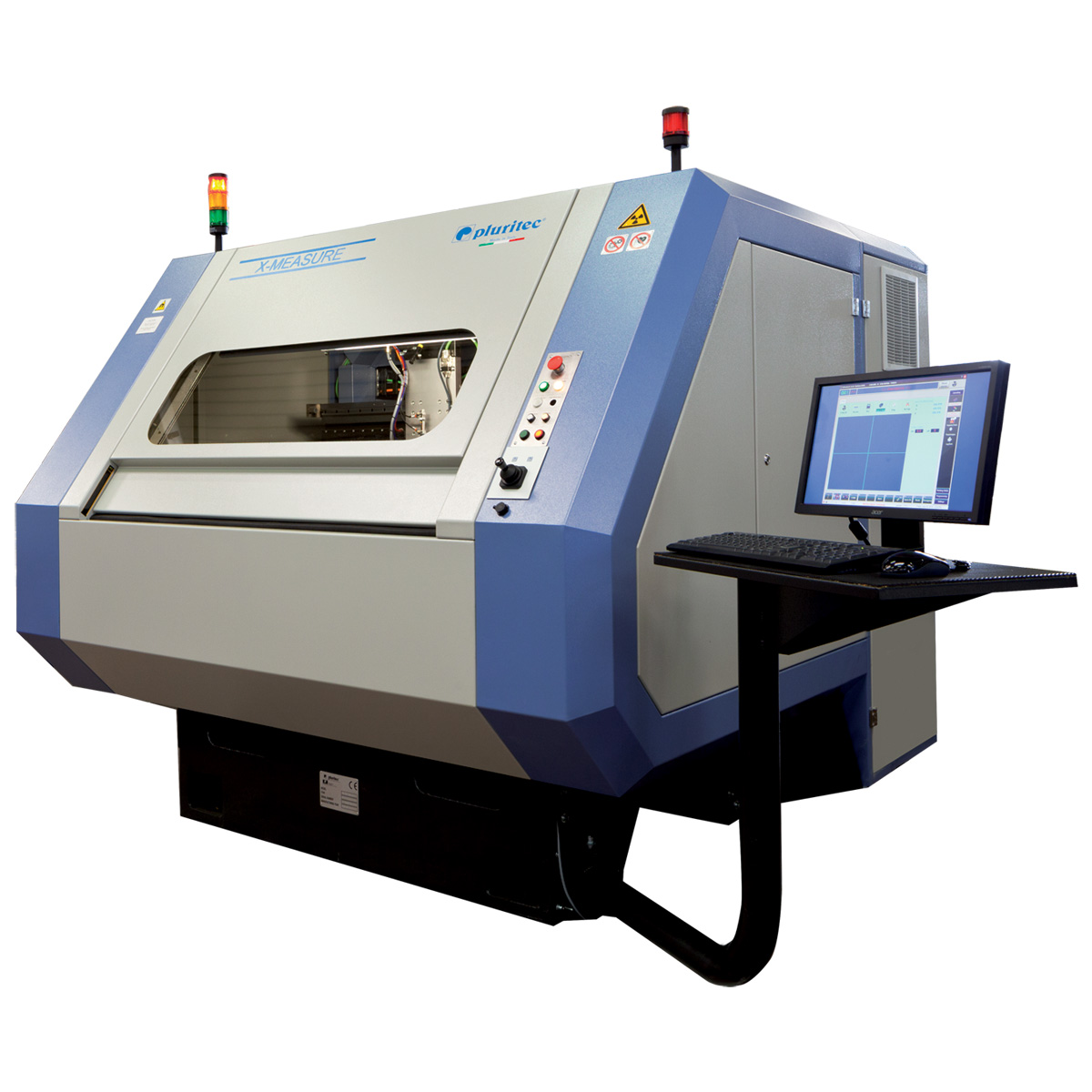

X-Measure

product features

Using the sophisticated X-Ray system detects panel’s inner layers targets and compute deformation compensation (linear, non-linear rotation, offset and scaling) drilling optimized tooling and reference holes.

Maximum versatility and flexibility that, in combination to a large working area, make a state of the art machine for high-end multilayer products.

Software includes a compressive database and a set of measuring and reporting utilities.

Designed for maximum accuracy and productivity

- 1 camera, 1 x-ray

- Heavy and stable machine body

- Table with gantry system and individual linear scales for maximum accuracy

- High-resolution camera

- Microfocus x-ray

- Large working area 1220x830mm (48.00×32.50″) – Optional 1220x950mm (48.00×37.40″)

- Large vision area 800x690mm (31.50×27.5″) – Optional 800x950mm (31.50×37.40″)

- Panel marking / Serialization

- Inner and outer layers code reading

- Complete statistical package includes statistical analysis, graphics, reports

- Automatic unloading and factory automation system available

- Factory 4.0 / M.E.S. ready

X-Measure XL

product features

Using the sophisticated X-Ray system detects panel’s inner layers targets and compute deformation compensation (linear, non-linear rotation, offset and scaling) drilling optimized tooling and reference holes.

Maximum versatility and flexibility that, in combination to a large working area, make a state of the art machine for high-end multilayer products.

Software includes a compressive database and a set of measuring and reporting utilities.

Designed for maximum accuracy and productivity

- 1 camera, 1 x-ray

- Heavy and stable machine body

- Table with gantry system and individual linear scales for maximum accuracy

- High-resolution camera

- Microfocus x-ray

- Large working area 1220x830mm (48.00×32.50″) – Optional 1220x950mm (48.00×37.40″)

- Large vision area 800x690mm (31.50×27.5″) – Optional 800x950mm (31.50×37.40″)

- Panel marking / Serialization

- Inner and outer layers code reading

- Complete statistical package includes statistical analysis, graphics, reports

- Automatic unloading and factory automation system available

- Factory 4.0 / M.E.S. ready

X-Vision

product features

The ultimate quality check tool. Using the sophisticated X-Ray system detects panel’s inner layers targets and measure.

Maximum versatility and flexibility that, in combination to a large working area, make a state of the art machine for high-end multilayer products.

Software includes a compressive database and a set of measuring and reporting utilities.

1 camera, 1 x-ray

- Heavy and stable machine body

- High-resolution camera

- Microfocus x-ray

- Large working area 1220x830mm (48.00×32.50″) – Optional 1220x950mm (48.00×37.40″)

- Complete statistical package includes statistical analysis, graphics, reports