Automation systems available for all machines:

Panel loading unloading

In line panel handling

Panel handling

Robotic solutions

Integration in existing lines

DEDICATED SOLUTIONS

Our team designs your dedicated solution based on your production requirements and constrains.

We can integrate our products with existing automation or preferred supplier choose by customer.

TECHNOLOGIES

Advance manufacturing solutions are available on all systems:

We use the latest technology in robotics and linear devices PLC or CNC controlled and ready for Factory 4.0 integration.

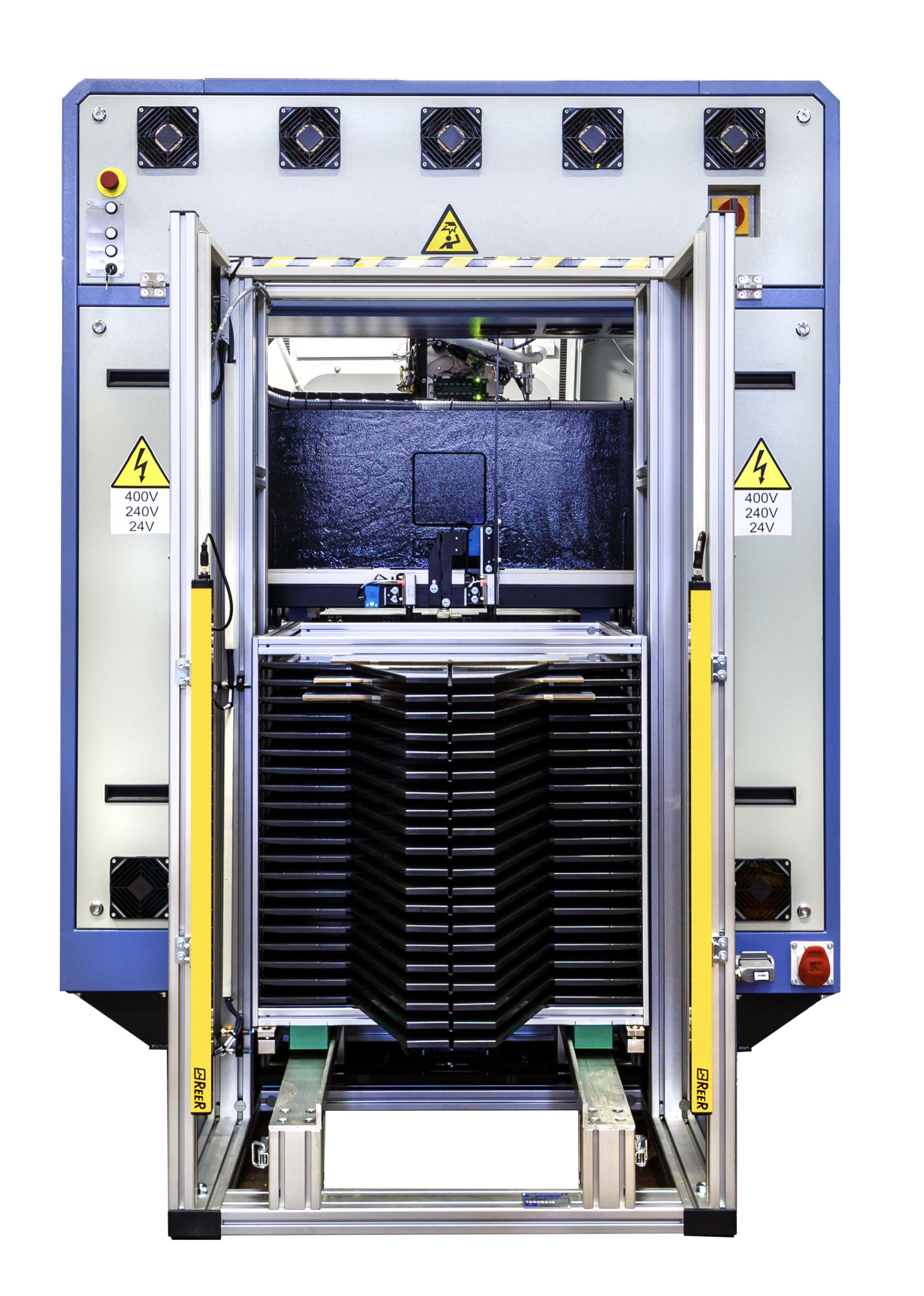

PANEL LOADING UNLOADING

product features

Automatic Panel loading unloading systems with 18 slots for drilling and routing machines.

Each slot can have a different job. Completed panel can be removed during machine operation and replaced with new jobs.

Program data and individual scaling factor can be automatically downloaded reading a QR code during loading.

IN LINE AUTOMATION

product features

In line panel loading and loading for rigid and flex materials.

Available stand alone with loading and unloading trolleys or in integrated with factory automation with roller benches, robots, age or other existing automation.

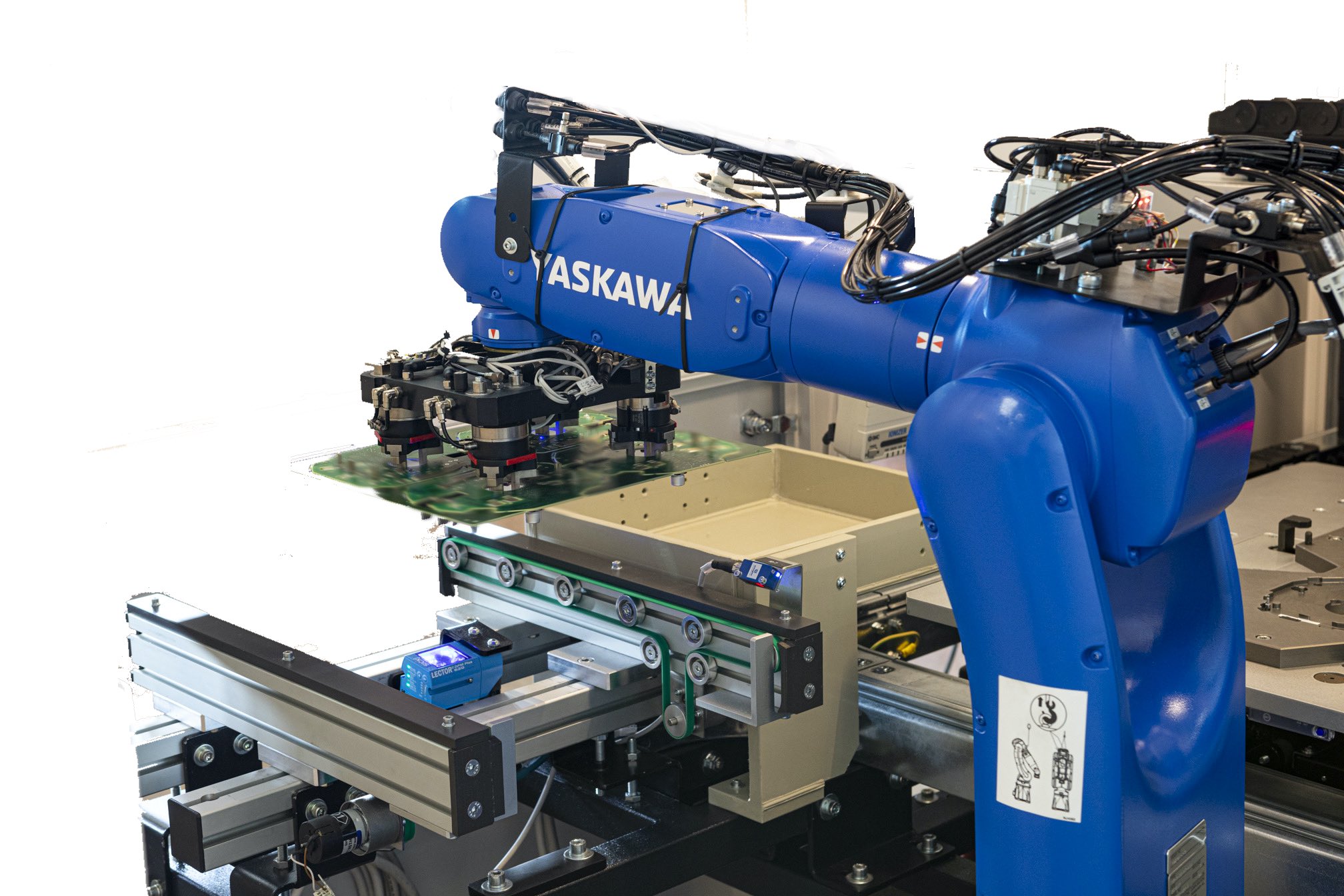

ROBOT INTEGRATION

product features

Flexible multi axis robot to handle rigid and flex materials of different dimension and thickness. Completely automatic lot, reject entry and backup management.

BACK LOADER | UNLOADER SYSTEM

product features

Back loader unloader system for rigid and flex materials (multilayer, core layers, entry material etc. )

Can load / unload from/to dedicated trolley, roller bench or AGV device.

LOADER | UNLOADER SYSTEM

product features

Loader unloader system for rigid and flex materials, core layers, entry material .

Inter leaves management.

LOADER | UNLOADER BUFFERS

product features

Back loader unloader system for rigid and flex materials (multilayer, core layers, entry material etc. )

Can load / unload from/to dedicated trolley, roller bench or AGV device.

x cut

product features

INTRODUCING XCUT – NEXT GENERATION X-RAY TOOLING AND PANEL PREP!

Dramatically reduce process time from lamination to drilling from hours to minutes while reducing 80% of the labor.

Automating these steps into one setup lets you “load panels and walk away”:

- X-ray drill/rout optimization

- X-ray sub-lam optimization

- Saw-cut lamination flash

- Bevel panel edges

- Spot-face/routout tooling holes

- Post-etch tooling

- Panel thickness measuring

- X-ray QR reading of cores

- Mechanical or laser panel marking

- Automated X-ray CMM